Sea urchin

harvest for

a sustainable future

HAVURs idea is to harvest sea urchins on scale to restore kelp forests. The aim is to reinvigorate coastal biodiversity and release the potential for kelp carbon capture.

Sustainable future

Across the world, kelp forest ecosystems are in sharp decline and 40 to 60% have already been lost. We believe that the sustainable future can be made by basing harvesting sea urchins on nature and science.

Science based

Havur’s approach is nature and science-based, and the technology is developed in Norway, drawing on 50 years of offshore technological development on an industrial scale.

Economic worth

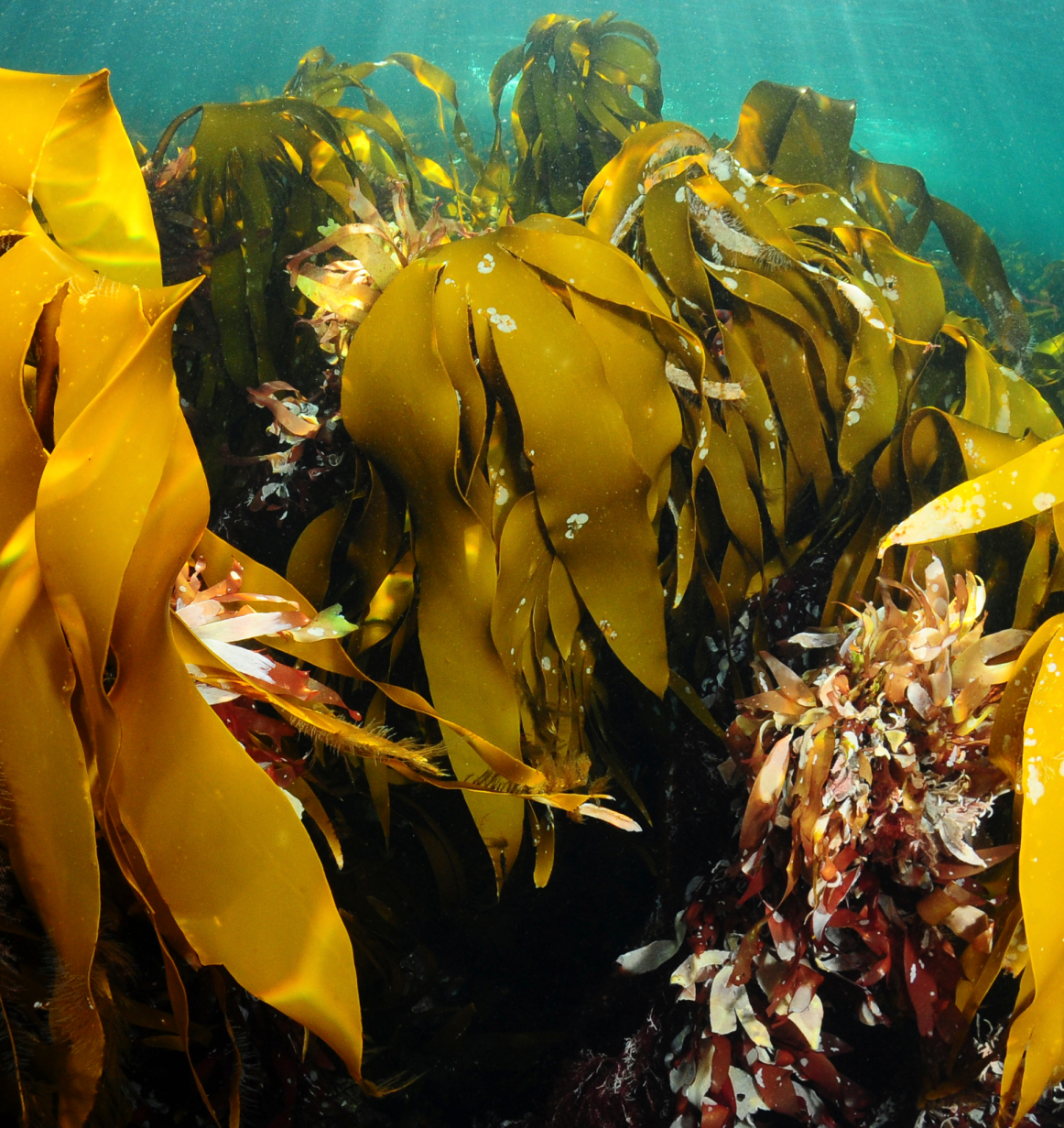

The value of Laminaria forests in the North Atlantic is estimated to at least €16.7 million per km2 per year. Re-establishing the kelp forest is a massive task that will take a lot of time and require immense resources.

Laminaria hyperborea kelp forest in North-Western Norway. © Lill Haugen/NTB.

Kelp forests –

and carbon uptake

Kelp and other macroalgae are effective at capturing and storing carbon in biomass, which helps reduce levels of CO2 in the atmosphere. Kelp has a fast growth and during their high production they take up CO2 from the water column. One of the advantages of kelp is that it leaves a significant portion of its biomass on the deep seabed, where a part can be sequestrated. This means that kelp forests permanently remove CO2 from the atmosphere, providing a tool for mitigating climate change. The global macroalgae biome binds as much carbon as the Amazon Forest. A group of scientists have estimated the global size of the macroalgal forests from 6.06 to 7.22 million km2 and that macroalgae bind around 200 million tons of CO2 each year, making them a valuable resource for mitigating the impacts of climate change.

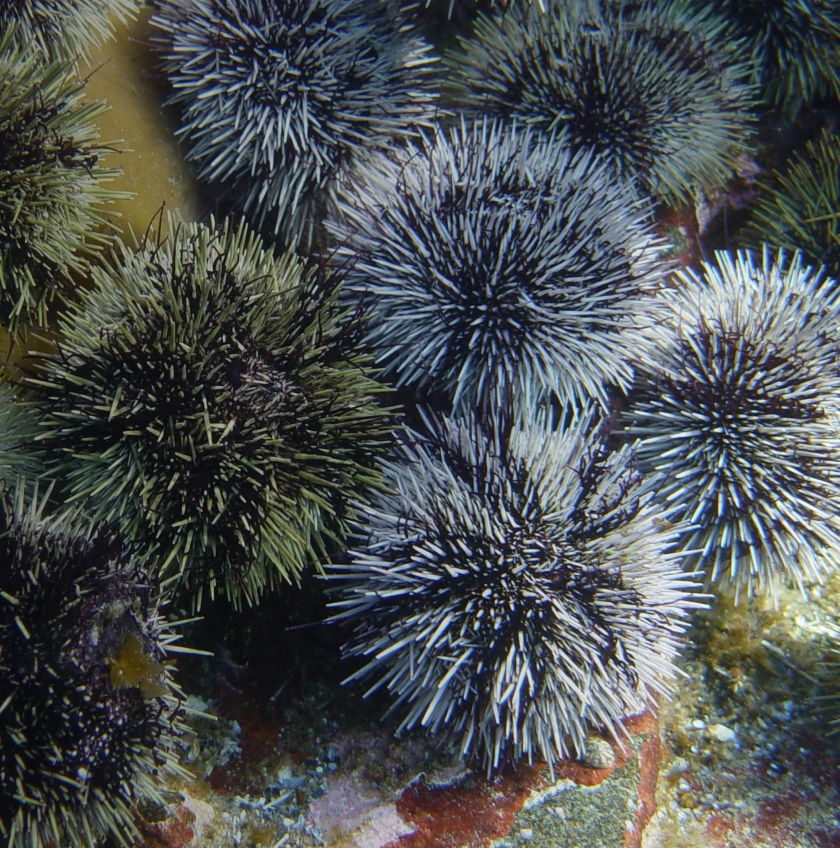

Why the kelp forests disappear

Kelp forests worldwide are facing several threats, causing rapid decline due to pollution, overgrazing, overfishing, ocean heatwaves, and coastal developments. An example of the impact of these threats can be seen off the Norwegian coast, where an explosion of the green sea urchin population in the early 1970s caused large-scale overgrazing and led to the transformation of once highly productive kelp forests into desert-like and persisting urchin barrens. This illustrates the damaging effect that overgrazing can have on kelp forests and highlights the need for active management and conservation efforts to restore and protect this important ecosystem, particularly in Norwegian waters where the grazing event took place at a very large scale. Removing sea urchins has been a successful way of restoring kelp forests and can be scaled up.

The green Sea Urchin (Strongylocentrotus droebachiensis) can

occur in high densities. © NTB.

Cod in kelp forest. © Per Eide/Samfoto.

The economic value of biodiversity

Sea urchins

An important sea urchin predator, Atlantic wolffish (Anarhichas lupus) at

Saltstraumen, Norway. © NTB

Why Norway?

Norway’s coastline is the second longest in the world, and if stretched out it would circle the equator twice, and a large part these northern coastlines are seriously affected by the sea urchins.

Norway’s second biggest industry is fishery and possesses some of the world’s most advanced catch vessels and process industry for fish and other marine species.

HAVUR is well positioned to take advantage of relevant catch- and process technology to catch and process sea urchins on an industrial scale.

HAVUR is starting in Norway but plans to expand operations to other countries based on needs and opportunities.

Team, Board and Scientific advisors

Emil Jeremic

CEO

Emil has more than 15 years international experience within the areas of strategy, organizational development, government liaison, planning and leading complex projects that demand expertise from various specialized professional environments.

Hans Gunnar Hansen

COO Marine/Vessel

Hans Gunnar has broad experience from the Maritime industry as well as from the supplier industry for process-lines towards the fishery-sector. He has been Director at Vard Aukra, a shipyard in the Vard-group. Hans Gunnar has also been COO in C Flow, one of the major companies delivering factories and process-lines for the fishery industry in Norway.

Line Skov Bakkemyr

Marine biologist

Line is an accomplished professional with extensive experience in the fisheries and aquaculture industries. She holds a master’s degree in Fisheries Science from The Arctic University in Norway and has over 11 years of experience as an HSEQ Manager in the salmon industry, with particular expertise in quality management and global system certifications. Currently, Line holds the position of Competence Management Specialist at A/S Norske Shell.

Kjetil Bøhn

Founder/Chairman

Kjetil worked four years as a journalist in Kapital after completing education at The Norwegian School of Economics in Bergen in 1996. He has been part of several start-ups since 2000, serving either as a CEO, part of the executive management team or as a board member. Since leaving his last CEO position Kjetil has started or been instrumental in revitalizing four companies, including Havur AS.

Even Bakkemyr

Board Member

Even is a highly experienced professional in Finance and Business Development, having held several management and board positions across diverse industries. He completed his education at BI Norwegian Business School and started his career in banking and finance, rising to the role of Assistant VP at Sparebanken Møre. He later became the CEO of Mosnes AS, a medium-sized investment company, before taking on the position of Group CFO at Sub Sea Services Group AS. Throughout his career, Even’s involvement in various board positions has provided him with extensive knowledge and a wide network in the fishing industry along the coast of Norway.

Tony Gustav Nervander

Board Member

Tony holds a master’s degree in marketing from Hanken School of Economics. He has long experience from several international companies as a (Country) Manager and within the areas of strategy, marketing and business-, organizational- and brand development.

Hartvig Christie

Scientific Advisor, NIVA (Norwegian Institute for Water Research), Marine biologist

Hartvig is a well renown and widely published marine biologist with 40 years’ experience in research of blue forests along the whole Norwegian coast. His research has focused on understanding ecosystems and effects of environmental impact through diving, mapping and scientific experiments.

Timeframe

April 2023

Phase II

R & D

December 2023

Phase I

Proof of Concept

June 2023

Phase III

Commercialization

Timeframe

April

2023

Phase II

R & D

June

2023

Phase I

Proof of Concept

December

2023

Phase III

Commercialization